Digital Picking POKAYOKE

System(D.P.P.S)

協立電機株式会社

KYORITSU ELECTRIC CORPORATION

Overview

・ The digital picking system is a mechanism that informs the operator of the target product and its quantity by blinking the digital display installed at each frontage of the shelf containing the product in the picking work to take out the product stored for shipping. ..

・ Digital picking systems have been introduced not only in product storage-type distribution centers, but also in parts removal work at manufacturing plants.

・ Pokayoke is a simple mistake made by humans, and this system is a system to prevent such simple mistakes.

・ The work that makes the most mistakes is the work of repeating the same operation in detail. This system uses a visual sensor to determine the mounting of parts and the misalignment of parts, so that incorrect parts and missing parts will not flow to the next process. This will reduce defective / scrap products, leading to wasteful cost reductions.

Advantages

・ Reduction of consumables by making it paperless

The picking list is no longer required to be printed, and the costs (paper, printing, printing equipment) are not required.

・ Improvement of work productivity

You can save the trouble of carrying around the conventional sorting list and searching for the product input destination.

・ Reduction of work mistakes

After hand-scanning each product individually, the number of instructions is displayed on the digital display, so the product may be misunderstood.

You can reduce mistakes in quantity.

・ Ease of work that even beginners can respond immediately

Because the barcode is scanned at the handy terminal, no product knowledge is required, even for those who work for the first time on that day.

You can start working immediately with a simple lecture.

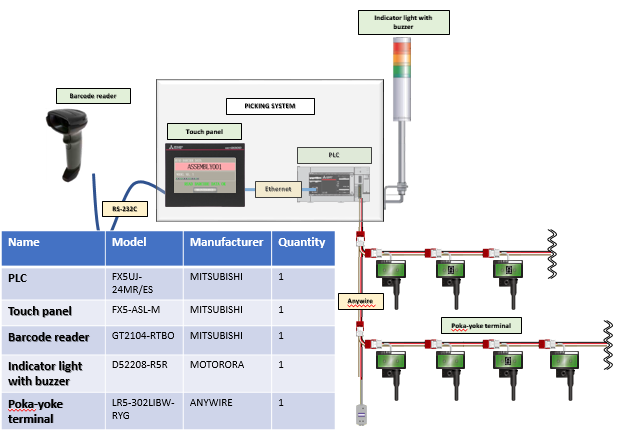

System configuration

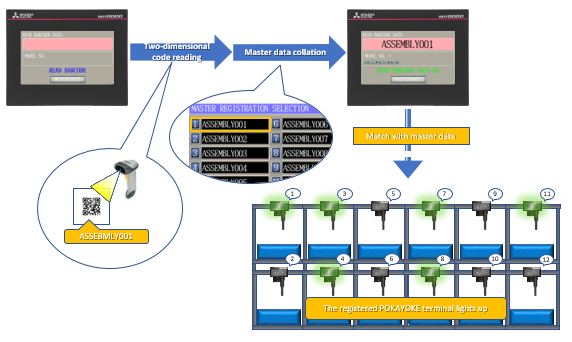

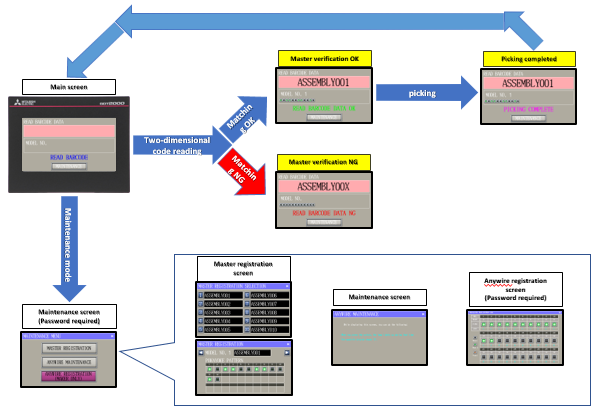

Picking function ①

・ When the 2D code is read, the pattern matches the master data.

The POKAYOKE terminal lights up.

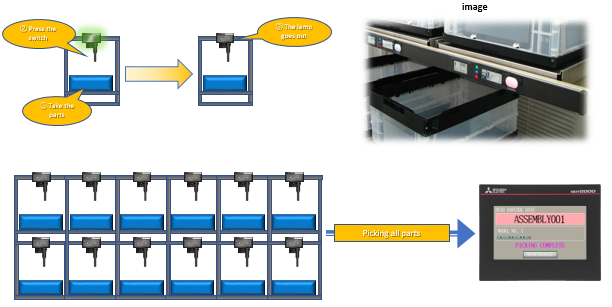

Picking function ②

・The picking order is free.

・ When you pick a part and press the switch, the lamp goes out.

・ Picking is completed when all parts are picked.

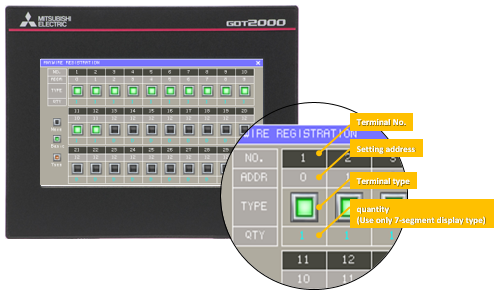

Poka-yoke terminal registration function

・ Up to 30 AnyWire POKAYOKE terminals can be registered. (Note 1)

・ When registered, the terminal address is automatically calculated and displayed in real time.

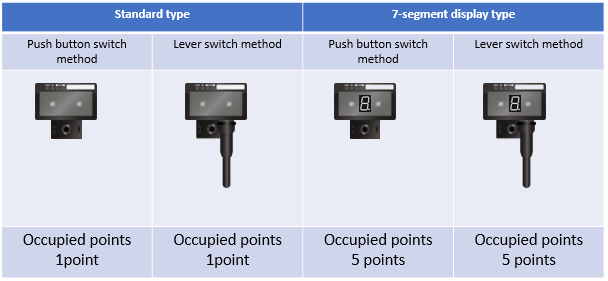

Note 1: Since the maximum number of points is 128, all 7-segment display types cannot be used。

Touch panel screen transition diagram

POKAYOKE terminal lineup

・ There are 4 types of POKAYOKE terminals that can be registered.

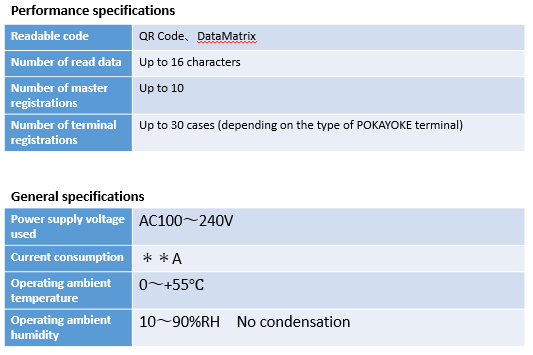

Product Specifications

“Digital Picking POKAYOKE System” package

It will be D.P.S using Anywire’s Pokayoke terminal using Mitsubishi’s inexpensive small PLC FX.

・A system aimed at improving efficiency in small to medium scale (2 to 64 shelves) picking work, kitting work, and sorting work, and preventing erroneous product mixing.

・ Target customers are for all industries that are engaged in assembly work.

・ For large-scale (100 shelves or more) D.P.S inquiries, we will cooperate with Ioi System to respond.

The only support for overseas technology is software replacement, application, and package.

* On-site adjustment, system setting, operator training, and other installation work will be handled by the current method.

In addition, SV dispatch is also possible if necessary. ・ Software replacement remote support is possible.

* Introducing GX-Works apps, etc …. can be handled at an additional cost.

If you need further product support please contact us.

Thank you.