IRONCAD

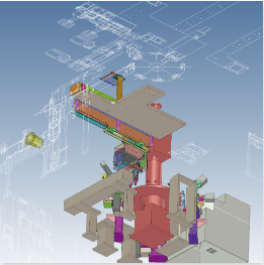

3D and 2D integrated environment

7 strengths of IRONCAD

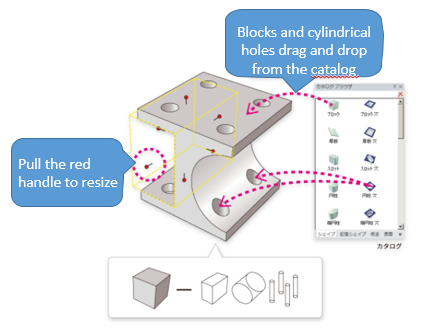

①Easy modeling

| With IRONCAD, you can create parts by simply dragging and dropping 3D shapes such as blocks from the “Catalog” into the 3D space. The “catalog” has various shapes and materials, and it is possible to design automatic machines, equipment machines, jigs, etc. that make heavy use of plates and cylinders without drawing sketches. |

|

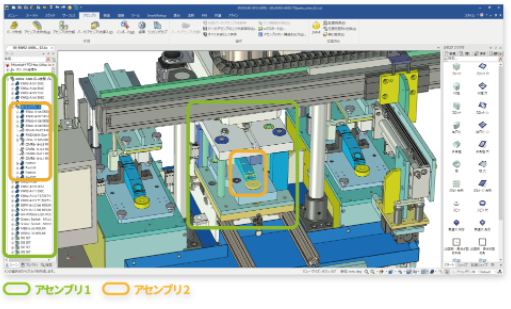

②Crisp concept file structure

| IRONCAD has the same file extension for parts and assemblies, so file management and conceptual design are smooth. After conceptual design and detailed design in one file, parts / assemblies can be saved externally with links. You can create and disassemble assemblies with the touch of a button. The assembly structure can be freely edited from the history. |

|

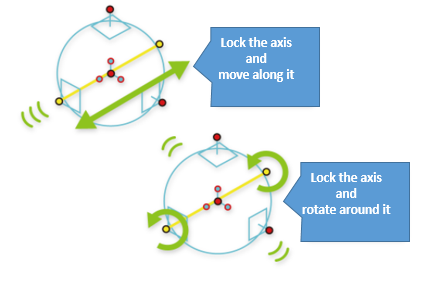

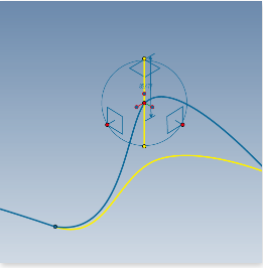

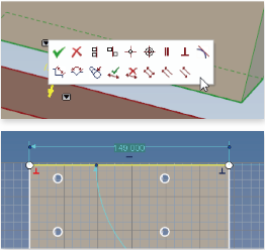

③ Easy to allocate

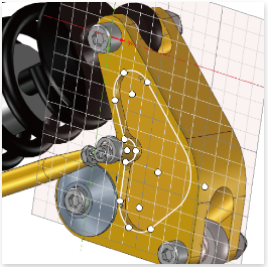

| TriBall can move, copy and position any objects in the 3D scene.

Complex positioning operation is possible without TriBall can be use to position objects :Shape, part, assembly, TriBall body, section figure, 3D curve, surface, joint point, face, light, camera, texture, contour, cut surface, animation pass etc

|

|

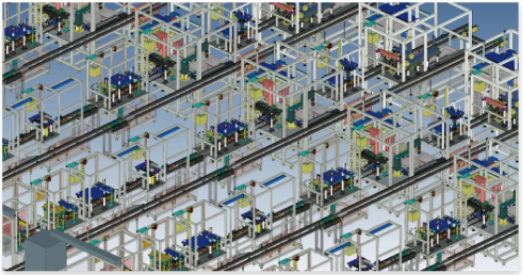

④ Support Large Assembly Mode

| Tens of thousands of assemblies can be manipulated smoothly without suppressing parts. Direct ediƟng of parts is also possible. Move, delete, undo, shape change features is done with a quick response. |  |

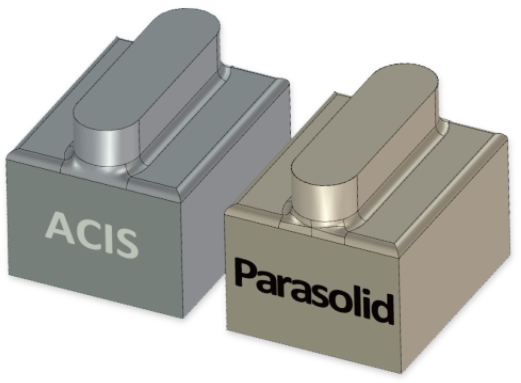

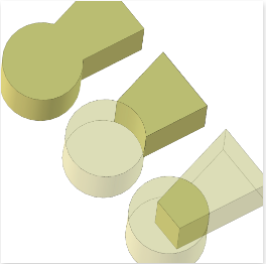

⑤ Dual kernel

| Has two kernels, ACIS and Parasolid. The kernel can be switched according to the shapes. Useful for creating complicated shapes and reducing errors when importing / exporting the data from other CADs. |

|

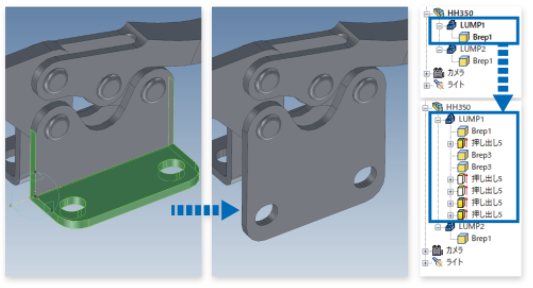

⑥ Direct editing or face by Auto-feature is useful for

editing the shape of the model imported from other CAD

| It is also possible to convert any shapes to IRONCAD features and edit them from the history generated at the same time |  |

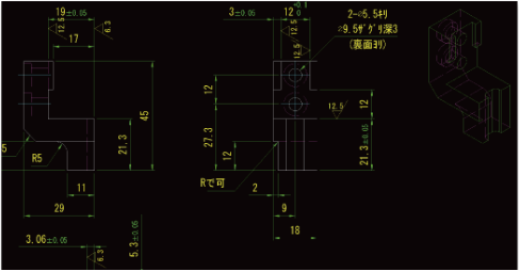

⑦ 2D-CAD with DWG compatibility

| It has the abilioty to can read, edit and save DWG, DXF files. And can also be used as a standalone 2D-CAD. There are compatibility of line type, layer, block, dimension style, text style, etc., attribute editing such as drawing border is possible. Shx font is also supported |  |

Main functions

|

|

|

|

| Extrude, Spin, Sweep, Loft 3D | 2D shape / sketch 3D | 2D curve · 3D curve 3D | Surface 3D |

| Provides the ability to create the models by creating sketches similar to other CAD products. May also be used to create shapes which are not in the standard catalogs. |

You can select the layers such as Center lines, hidden lines and import DWG · DXF as a cross section. 3D models can be created using this Import Referrence 2D. | Create an accurate curve by specifying profile and tangent points. (Where to use: 3D sweep, guide curve loft, surface shape creation etc) It is also possible to create intersection curves, projection curves, UV curves. |

The ability to create surface shapes from faces or 3D curves. It is also possible to reference existing parts and the surfaces of an imported model. The created surface can be thickened or used to cut a solid model. |

|

|

|

|

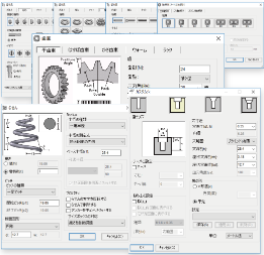

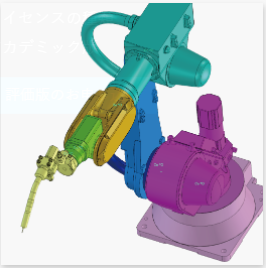

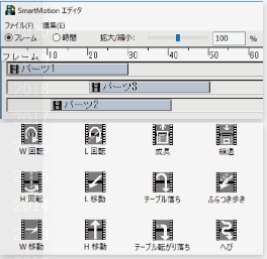

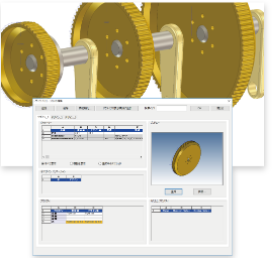

| Boolean 3D | Mechanical parts 3D | Mechanism mode 3D | Animation creation 3D |

| Create one part from multiple parts. You can create a Union/Subtraction/Intersaction boolean. You can edit individual shapes from the history afier the boolean creation |

Mechanical parts such as bolts, taps, special holes, bearings, springs, gears etc. can be easily created | Verify the collisions and interference of compoments by assembling and positioning constraints |

Simulate motion by animation. Various animation passes are available in the catalog. It can also be used in the mechanism mode. |

|

|

|

|

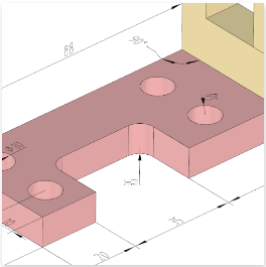

| 3D PMI (Product manufacturing information) annotation 3D |

Positioning constraints / Geometric constraints 3D |

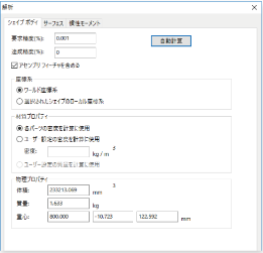

Analysis · Range of automatic calculations 3D |

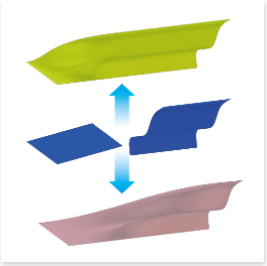

Design variations 3D |

| Dimensions, notes, tolerances, surface finish, welds, datums can be placed in 3D models. These can be passed to the 2D environment (CAXA Draft) |

Align parts’ position or asign angle of parts when creating Sketch. The contraints can be asigned freely, as required. | Automatic calculation of mass property such as volume, mass, surface area, center of gravity, moment of inertia, etc. Are all possible BOM You can create automated BOM by defining your own custom properties. Excel output is also possible |

You can adjust variations of assembly / feature / part by seƫng parameters such as dimensions, etc. Numbers entered in the parameter table are automatically apllied. |

|

|

|

|

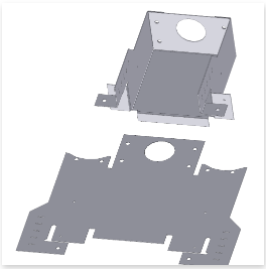

| Sheet Metal design / Unfold 3D | Rendering 3D | 3D → 2D Link 2D | Tolerance, symbols, specialized feature 2D |

| As bending and punching shapes are available in the catalog, you can design sheet metal with drag & drop. Parts created by shelling and imported parts without history can be unfolded. Support for 2D flat pattern drawing, 3D conversion and bending. |

3D environments can be shown realistically by seƫng exposure, shadows, background, etc. It is useful for creating photorealistic presentations and brochures |

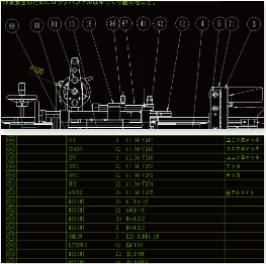

Projection drawing can be easily created (.exb 2D file extension). 2D contents will update automatically when the 3D model is changed. Property information of 3D model can also be output to BOM for creating assembly and parts drawings. | Dimensions, tolerances, notes, and symbols necessary for creating machinery drawings. For exmaple, library of dimensional tolerance, geometrical tolerance, welding symbol, surface finish symbol, note, center line, shaft drawing, gear drawing, bolt · tap… |

|

|

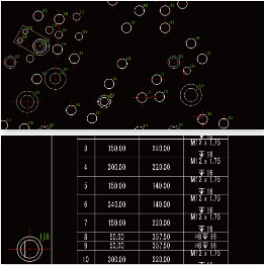

| Auto dimension/ Auto hole table 2D | Bill of materials, Item No 2D |

| Auto dimensions, auto hole table can be created. It is possible to drastically reduce the time and effort to fill in the dimensions | You can automatically create parts lists and item numbers associated with parts and assemblies. BOM corresponds to both 3D scene and 2D drawing. Output to EXCEL is also possible. |

Please contact us if you need assistance.

Thank you